Table of Content

Once you have your furnace and molds ready, you can easily melt your aluminum in your home foundry to create castings of your favorite parts without much effort. The best part is that it can be done at a fraction of cost of the original part purchased from the market. We hope this DIY home foundry and aluminum casting guide helps you practice your metal casting hobby and create your home foundry to create parts and components out of aluminum. A simple and well-designed furnace ensures ease of operation and efficient metal melting in a home foundry.

Factored in are contemporary concerns, including access to the internet and cell phone service and the importance of an effective security system. Chapter summaries drive home key points for success, and a list of resources directs readers to key information. Do you aspire to live a green or zero-waste life, but just don’t know where to begin?

Aluminum Casting At Home – DIY Aluminum Foundry & Molds

Depending on the size of castings you are required to make, you can make the flask large or small. If required, the depth of the flask can be increased by fitting a simple 4 sided cheek between the components. Imagine, you have just found that you can melt and cast metals in your own backyard foundry and you feel excited at the possibility of making your very own metal castings. The excitement grows as you begin to slowly understand the; how, what & when of this traditional metal craft. You’ll be inspired to dive deeper into green living and feel empowered by your choice to help the environment and create a healthier household. Many people across the globe produce their own superior quality bronze and aluminum castings for vintage and veteran motorcycles and cars.

It is quite easy to construct a furnace using the scrap material found around the workshop. The only material you need to buy is the high-temperature resistant refractory, some brass connectors and brass rod. Using your basic metal working skills, you can quickly make the furnace to complete your home foundry for DIY metal casting.

Build Your Own Home Metal Foundry

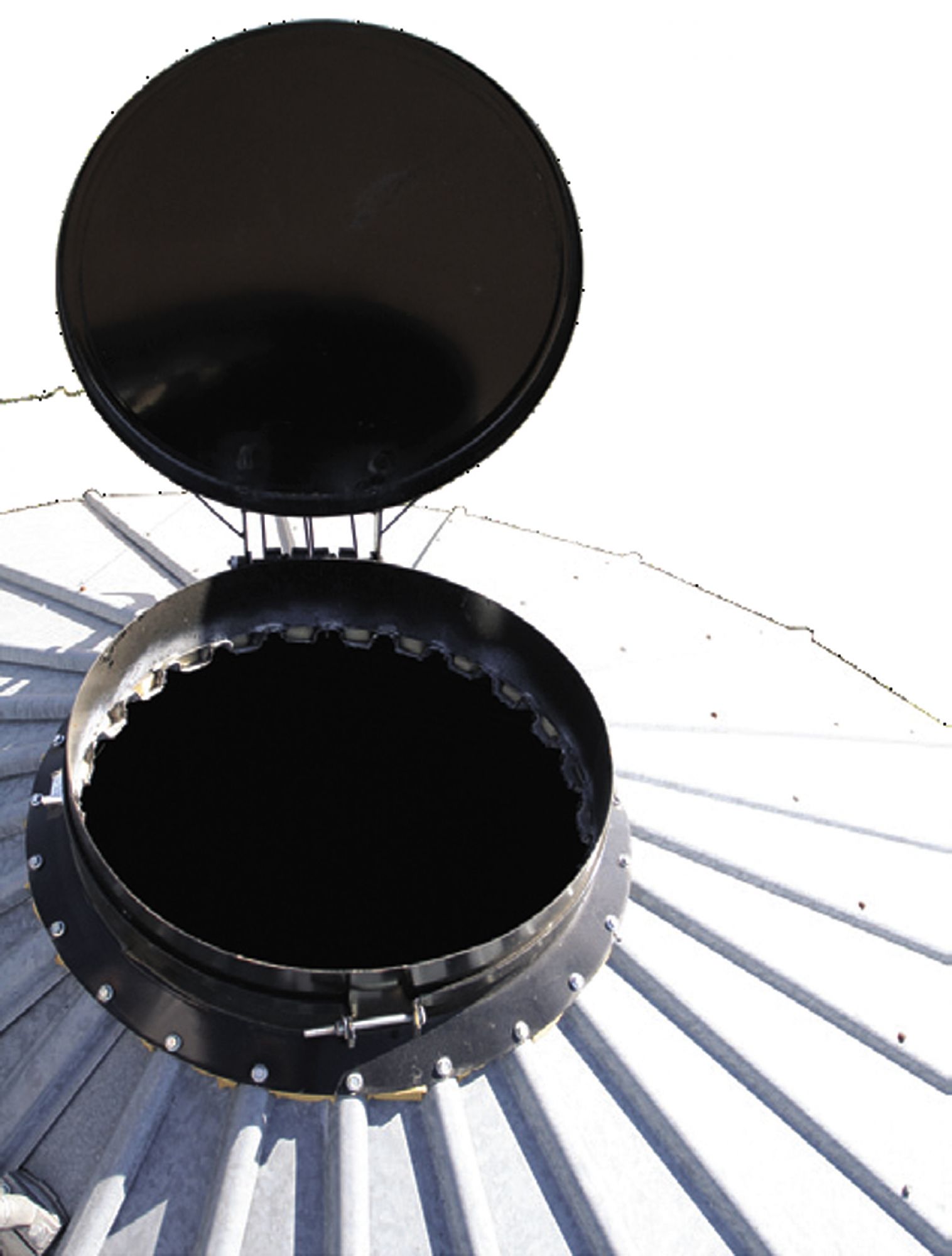

The hole should be sufficiently to fit a 16" section of 1-1/2" feed pipe. After this, weld the assembly to the wall of canister, with the elbow pointing in upward direction. Next, make a hole in the middle of lid section, and weld a small length of 2 & quot the muffler tubing in place, permitting it to protrude below the lid's lip lightly. Then fix some handles—made from small pieces of 1/8" X 3/4" flat stock and 6" pieces of 1/2" pipe—to the sides of the faces of container. John Vivian's guide to mastering the ancient art of metalworking takes you from basic tools to working with metals as various as bronze and high-carbon steel.

We have sent supplies all across Australia and even to a few places overseas. Due to the extreme temperatures generated within the furnace, its floor, inner walls, and lid should be lined with the refractory material. The outer skin of the smaller of the two vessels should be coated with oil to allow for its easy removal. Next, place the vessel upright on top of the elbow and the "pasty" base pour, ensuring that it is centered evenly within the drum of furnace. Then go ahead to fill the wall cavity with refractory in the same manner, you did the bottom. Complete the job by inverting the lid and lining it, to the degree of the muffler pipe, in a similar manner.

Featured work at KIT Royal Institute

They are hobby metal professionals who like to cast metals to fulfill their creative desires or to make a special part or component, which is difficult to find in the market. The sand mold creating process involves use of a metal, furnace, sand mold and pattern. The aluminum is melted in the furnace and then poured into the cavity of the sand mold formed by a pattern. It is packed around a pattern which is the replica of the casting shape. The metal is melted at home and poured into the molds and when it has cooled and solidified, it is taken out as a shiny new metal casting. A hobby metal casting professional can create things to be used for special projects, vintage automotive parts, antique restorations and rebuilding old workshop tools.

For more information on our metal melting and smelting furnace kits, get in touch with the experts at Cast Master Elite today. We have been doing metal casting since 2001 and started out using Petrobond Sand. As a home foundry we know how hard it is to find the tools you need to create great castings. Except the crucible, most or all of the foundry equipment can be easily produced at home for little or no cost. Powerful gas-fired soldering and melting furnaces form the backbone of a productive foundry classroom.

The principles still apply today and whilst it would appear to be aimed at the novice, there is much for the experienced. Being well illustrated with cross sectional line drawings, the spirit of the book appears to be that virtually any shape is castable. This is an easy to read book which I think will be a useful addition to the bookshelf of anyone interested in metal casting. Although some of the techniques may be dated, it contains much information which provides inspiration and be a source of ideas and work around for solving casting problems.

If you’re interested in casting other sorts of metal, you can check out our article “Metal Casting At Home – A Getting Started Guide” here. Most of the foundry equipment is easily available for little or no cost. A good home foundry can be setup for a fraction of the cost when compared to buying a metal part. When creating a part or component, you can easily make other components by pouring some extra sand. All about industrial applications of metal casting technologies in Automobile, Industrial Machinery.

In depth analysis of industry process, recycling, and environmental issues of the cast metals industry. With a little sense of mind and resourcefulness, a good foundry can be setup for a small fraction of the cost of one metal you were going to buy from the market. Full-station workbenches, bellows, Petrobond sand, flasks, and accessories help build out a new classroom from scratch or restock an existing room for a new school year. High-quality names like McEnglevan, Fallbrook, and Holland Manufacturing ensure your equipment will outlast years of hard use from hundreds of students. Absolute top location, living adjacent to the park, with the feeling of living in the woods, surrounded by greenery. The apartment also features a large open plan kitchen/lounge area with lovely fireplace.

The simplest and the most affordable material is a high-quality casting plaster available at an art supply store. It is a good idea to first design the part so that a single-piece, open-faced mold works every time you want to create the part. This gets you rid of the problem of dealing with cope, risers, sprue and alignment.

A student getting burned is the last thing you want to deal with but thankfully, one of the easiest accidents to prevent. Thanks to your insightful ebook I now know how to deduce what pattern configuration to use basically from any casting work that needs doing! Compound flasks, soldiers, pattern sweeping, balance cores etc, are all terms and techniques that I now understand. Thanks again for a wonderful book and the preface in the book 'Knowledge is Power' certainly is an appropriate adage as my pattern making knowledge has been improved ten-fold.

Based at a national heritage site in Amsterdam, KIT Royal Tropical Institute is an independent centre of expertise, education and hospitality dedicated to sustainable development. We use all the products that are sold in our shop so it’s easy to provide a 100% Guarantee. It offers an excellent overview of the many options available, allowing the reader to make the best choices for their individual situation during the design, installation, and operation of a solar electric system. All the basics are thoroughly covered, such as well water, septic and sewage disposal, and off-the-grid energy options .

You need not find a source or pay for metal parts which you require for some mechanical device or vehicle. Moreover, you have put to good use all those small pieces of scrap metal, which were good for little else. Next time when you need the same component, you don't have the make the mold and some extra efforts, which you did the first time.

No comments:

Post a Comment